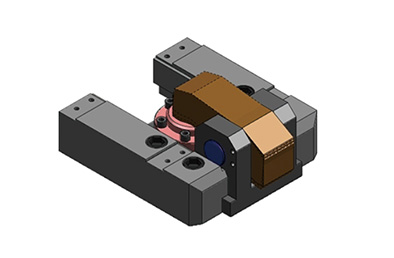

| IMM Capacity (T) | Hyd.Clamps Type | Unit Clamping Force (T) | Fixed Platen Qty. | Movable Platen Qty. | Max Clamping Force (T) |

| 60-120 | YM2 | 2 | 4 | 4 | 8 |

| 160-250 | YM4 | 4 | 4 | 4 | 16 |

| 280-380 | YM6 | 6 | 4 | 4 | 24 |

| 470-530 | YM10 | 10 | 4 | 4 | 40 |

| 600 | YM10 | 10 | 6 | 6 | 60 |

| 700-900 | YM16 | 16 | 4 | 4 | 64 |

| 1000-1300 | YM16 | 16 | 6 | 6 | 96 |

| 1400 | YM25 | 25 | 4 | 4 | 100 |

| 1600-1850 | YM25 | 25 | 6 | 6 | 150 |

| 2100-2800 | YM25 | 25 | 8 | 8 | 200 |

| 3300 | YM50 | 50 | 6 | 6 | 300 |

| 4000 | YM50 | 50 | 8 | 8 | 400 |

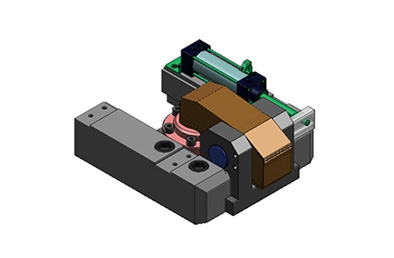

*Easy operation.

*Economical and practical.

*With SMC automatic cylinder to increase automation.

*Reduce labor intensity.

*Shorten mold change time.

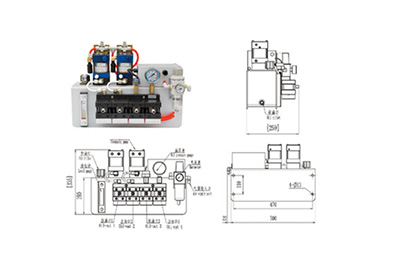

Pneumatic hydraulic pump station

1.This is oil supply system of the whole QDCS, double and single pump design for power output.

2.When pump station stops pressurizing, the system is in low pressure state and no energy consuming.

3.Using patented technology group valve, Independent four circuit design, when power off and air off, the system self-lock still keeps the pressure.

4.Pneumatic components adopt Japan SMC, and imported seals.

PLC control

1.Using omron PLC control system.

2.PLC communicate Intelligently with machine and multi-layer safety interlock avoiding operational errors.

3.Specific single side die change function, double confirmation about avoiding operational errors. Equipped with key switch to prevent the artificial operational errors.

4.If machine or die change is abnormal, then clampers starts warning and injection machine stop working automatically.

5.Integrated operation panel, simple operation.

6.LED indicating light display the allowing state of whole system.