| Max. Clamping Force(Kn) | Platen Dimension(mm) | Max. Load Capacity on Lower Platen (T) | |

| HMG-70JM1008 | 700 | 1000*800 | 4 |

| HMG-120JM1411 | 1200 | 1400*1100 | 8 |

| HMG-160JM1613 | 1600 | 1600*1300 | 16 |

| HMG-200JM1815 | 2000 | 1800*1500 | 20 |

| HMG-280JM2016 | 2800 | 2000*1600 | 25 |

| HMG-320JM2218 | 3200 | 2200*1800 | 36 |

| HMG-350JM2520 | 3500 | 2500*2000 | 42 |

| HMG-400JM3020 | 4000 | 3000*2000 | 50 |

| HMG-500JM3020 | 5000 | 3000*2000 | 60 |

| HMG-500JM3025 | 5000 | 3000*2500 | 60 |

| HMG-600JM3525 | 5000/6000 | 3500*2500 | 70 |

| HMG-600JM4025 | 6000 | 4000*2500 | 80 |

| HMG-600JM4030 | 6000 | 4000*3000 | 90 |

| HMG-800JM4235 | 8000 | 4200*3500 | 160 |

| HMG-1000JM5042 | 10000 | 5000*4200 | 210 |

| HMG-1200JM6548 | 12000 | 6500*4800 | 300 |

*Max. clamping force and platen dimension can be customized

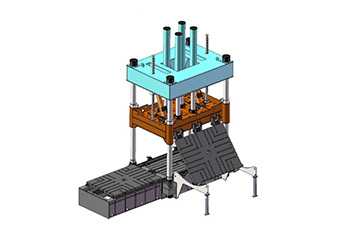

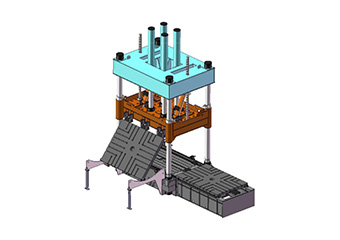

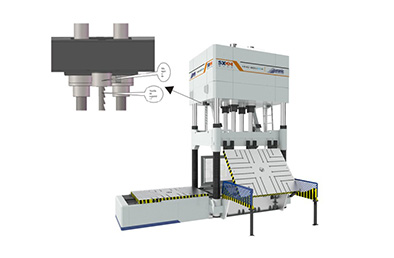

Standard left side

Optional right side

Standard one way

Optional opposite way

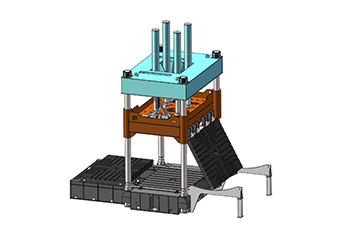

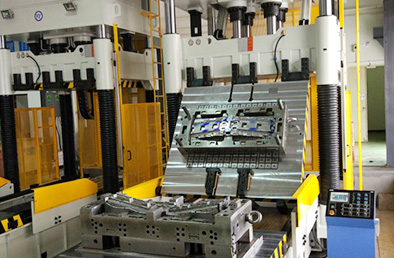

It allows you to conveniently match all the parts of the mould in more comfortable position. Check and finish the die at one place in more ergonomic position.

No more dangerous ways (such as cranes and forklift trucks) to handle the molds.

No more spotting on injection molding machines, which are costly and difficult to access.

Optimal accessibility and ergonomics by means of swiveling and tilting plates.

Low operating and maintenance costs.

High Flexibility.

Considerable reduction of correction grinding through reproducibility.

Trials of hydraulic slides, auxiliary cylinders and ejectors can also be done in single operation.

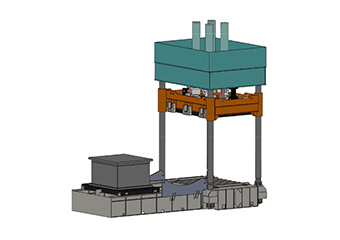

Rotary Table

Lower Platen has rotary function from 0° to 120° to 240° or 0° to 180°. This function is mainly used for the tryout of two-color and three-color molds.

Machine can be equipped with electric permanent magnet chuck to furtherly ensure the precision of multi-color molds and improve the mold tryout efficiency.

The lower platen can be tilted both front and back by 70°

SXKH two way type die spotting press has the optional function of 70° tilting front and back, for the lower platen.

This function enables lower platen to tilt by 70° once lower platen move out. Thus operator can repair mold without bend down, which greatly eases the lumbar muscle strain injury of operators.

Siemens PLC System

SXKH has more than 10 years’ experience to use PLC system in Die spotting press. We use new S7-1200 Version as the standard configuration of the Press.

*Equipped with the PLC system

*Remote control module is optional

*Control and monitor press

*All the parameters can be settled and saved

*Memory function available-Mold database

*A wide variety of signal modules for input and output

Hydraulic Servo System:(Optional)

*Servo System provide more economy way to operate Spotting press(60% energy saving. Provide much better stable holding force.

*Provide much better stable holding force.

Pneumatic-Mechanical Locks for Moving Base: (Optional)

*Two safety locks ensure the upper platen can be locked at any position when upper platen goes up or down. This is a mandatory device specified by EC rules.

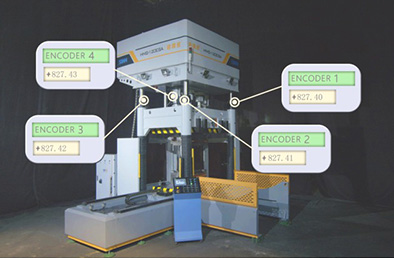

Electronic Moving Base Parallelism Checking System:(Optional)

There are four encoders at each tie bar to measure parallelism in real time. The touch screen shows the state of encoders working continuously. With the low pressure mold protection function, the mold can be prevented damage in the case of improper operation by employees.

QDC-Quick Die Change System (Optional)

We will provide additional two way to reduce mold clamping time.

*Electricity permanent magnetic working table.

*Hydraulic clampers.