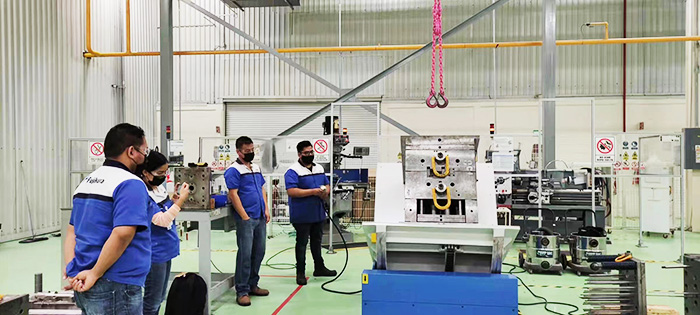

How to improve the practicality of the tool mover ?

As an auxiliary equipment for molds, the tool mover is a low-key but highly practical equipment. The practicality of the tool mover is an important symbol to reflect the use value of the tool mover.

For enterprises engaged in mold manufacturing industry, tool mover can not only reduce personnel danger during mold maintenance, but also improve mold reliability and stability, extend the service life of mold, and improve production efficiency.

In order to better play the practicality of the tool mover, mold enterprises need to start from the following aspects:

Regular inspection and maintenance of tool mover

There should be a special person responsible for regular inspection and maintenance of the tool mover, regular troubleshooting, regular cleaning of the tool mover, regular lubrication of components, pay attention to dust-proof, moisture-proof, anti-freeze, anti-corrosion and other work, do a good job of regular maintenance can extend the service life of the tool mover.

Strengthen the technology and training of employees

The technical level and maintenance level of the operator have the greatest impact on the service life of the tool mover. It not only affects the efficiency of the tool mover, but also often causes undue damage to the tool mover due to improper operation. Therefore, the reasonable use of the tool mover must grasp the training and assessment of the operator and improve the operation, repair and maintenance ability of the operator.

Establish a sound equipment file

Establish the file of the tool mover, which should contain the basic information of the tool mover, testing records, repair records, maintenance records, spare parts replacement records, etc. At the same time, after completing new inspection, repair and maintenance tasks, the equipment records should be updated in real time.

Improving the practicality of the tool mover helps to improve the reliability and stability of the mold, so as to better create greater benefits for the enterprise.