Do you want to make mold turning easier and safer?

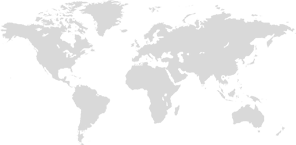

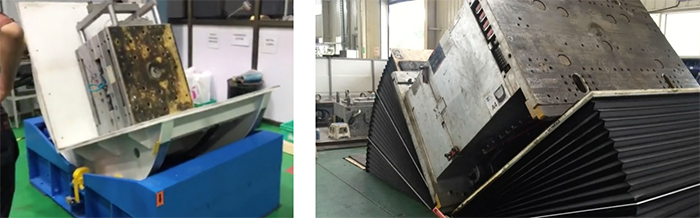

In the mold production process, the traditional mold tilting method may cause accidental danger, resulting in damage to the workpiece, endangering the personal safety of the operator, and damaging lifting equipment.

In fact, a tool mover can realize the 90 degree and 180 degree turning operation of converting the mold from horizontal to vertical or from vertical to horizontal. Especially when repairing large and medium-sized molds, tilting mold is labor-consuming, dangerous and costly, too mover as newest equivalent equipment of mold tilting device, are getting increasing attraction of global tools and die makers. It is convenient, labor-saving and safe to open, close and lift the mold. Tool mover is an indispensable auxiliary equipment for the stamping workshop, and for vertical die spotting press machines.

SXKH tool mover is mainly used in injection molding industry and mold production industry, and also used in turning welding workpieces. It has the characteristics of high efficiency and strong safety performance. SXKH has been designing and manufacturing Tool mover for decades, whose tool mover has the following advantages:

1. They provide two options of motor drive and hydraulic drive tool mover, catering for the diverse demands in tilting mold. which are economical and time-saving, free of machine maintenance;

2. For hydraulic tool mover, its entire hydraulic system can be placed underground, occupying a small area.

3. Imported electrical accessories are adopted, which are safe, reliable and easy to operate.

4. CE Certificated.

5. More than ten years of experience in research and development of tool mover.

With the development of industry automation and intellectualization, a type of professional tool mover would play a far greater role in the upgrade of mold turning process.