Method of Mold Inspection

Mold inspection is one of the most parts of mold production. Generally, small and medium-sized molds need one to three times of mold testing, and large and medium-sized molds need three to five times. The more complex the mold is, the number of mold testing is higher. The number of mold inspection times is related to the Die spotting machine, the quality of the operator, mold design and production quality, etc. At the same time, to some extent, the mold inspection reflects the technical level of a mold factory.

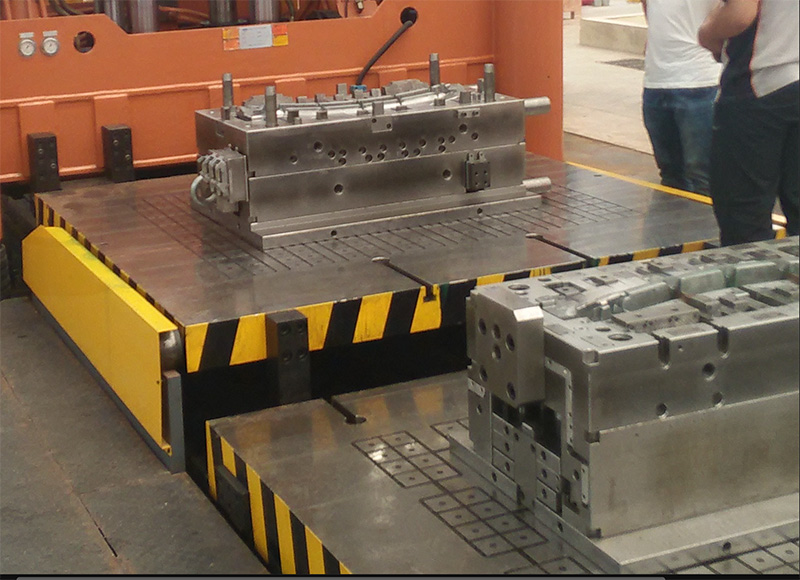

In fact, mold tryout seems a simple work but it is the highest technical process. Like auto parts mold, it’s complex, not only parting line is irregular, but also include a number of sliders and ejectors. Although mold fitting is a complex work, it can use a effective device-die spotting machine. Die spotting press is the most sure and safe way to check the butting of cavity and core. SXKH industry is specialized in four pillar type with high precision die spotting press and has more than 10 years experience. SXKH has helped many tool makers work in safety, efficient and economic way. Also a high effective device-mold inspection machine is recommended. Now SXKH Mold Inspection Machine is a type of the multifunctional and convenient mold inspection machine. It can be equipped with Electro-permanent magnetic chuck, which can easily control the mold titling and place so precisely. By mold inspection machine, the mold inspection process becomes more effective, time-saving and economical.

The most comprehensive reflection of the level of the mold is the sample provided by the last test. Usually the sample is sent to mold buyer,the inspection results will be as an important basis for the acceptance of the mold. Whether the basic size of the sample is correct or not can reflect precision of mold manufacturing .

1. Inspection of basic dimensions of products

Firstly, we should observe whether its overall shape meet our demands or not once we get mold sample. Whether the basic shape is in line with the product design idea and then test the basic size of the product .

2. Inspection of fitting size of products

The fitting size of the product refers to the fitting size of the product between the product and the relevant components, including the local fit size and the overall relative position size.

3. Trial assembly inspection

When the inspection of the basic dimensions, contour dimensions and dimensions is finished and it is considered that the design requirements are basically met, the trial assembly inspection can be conducted. This is a very important means in product inspection. It can verify the matching dimensions and the space surface.

4. Inspection of mold appearance quality

When the pre-installation meets the requirements, it is necessary to carry out a comprehensive inspection of the apparent quality of the parts. At this time, the apparent quality refers to whether the apparent quality meets the requirements without the presence of common defects.

5. Dynamic and static balance inspection

Dynamic and static balance tests for high speed parts. Impact resistance test, strength test and high temperature test for demanding high strength parts.

After the complete inspection of molds, the mold should be accepted. As mentioned earlier, the mold that can provide a complete sample, the overall structure can be regarded as reasonable. The other parts of the mold should still be carefully checked. The machining accuracy of the structure parts of the mold, the insert way, the heat treatment means and other factors directly affect the service life of the mold.